Klüber Speciality Lubricants

Ranked the world’s #1 specialty lubricants by leading Original Equipment Manufacturers (OEMs).

Make the switch to Klüber speciality lubricants and see the difference in your plant’s performance.

Klüber Lubricants are globally recognized for providing the highest component protection against lubrication related failures.

Klüber range of speciality Lubricants

Lubricating sprays

Corrosion inhibitors

Process lubricants

Bonded coatings

Your advantage with Klüber Lubricants

Eliminate downtime almost 100%

Speciality lubricant solutions to stop frequent component failures common with basic lubricants.

Significantly low maintenance costs

Your maintenance and component replacement costs will be significantly reduced.

Maximum equipment availability

Reduced downtime will mean high equipment availability and increased production.

Select the right speciality lubricant for your plant

1. Lubricating greases

Lubricating greases for demanding applications

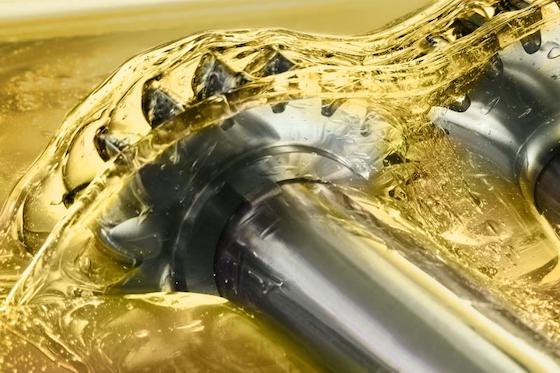

2. Lubricating oils

Performance speciality oils

Long-lasting and stable lubricating oils that offer:

– sustained high-performance even during high speeds, heavy loads and high temperatures

– excellent wear protection

– low maintenance and operating costs due to extended oil change intervals

3. Lubricating and assembly pastes

For assembly and friction points exposed to extreme conditions.

Recommended to keep assembled surfaces separate in:

– high-temperature applications of up to 1200 °C

– enormous compressive loads

– preventing fretting corrosion

4. Sprays

Sprays for spot application and re-lubrication of areas difficult to access

Lubricant sprays ensure quick and easy lubrication and re-lubrication of areas difficult to access and for spot application.

5. Corrosion inhibitors

Industrial corrosion protection agents

6. Automatic lubricant dispensers

For continuous and efficient lubrication to prevent component failure

Highly recommend for continuous lubrication and protection of:

– critical components; motors, pumps and bearings

– difficult to access lube points e.g at height

Typical Klüber Applications

Cement Plants

Tough conditions in the production of building materials.

Air compressors, Assembly pastes, Compressor, Coolers, Crushers, Electric motor bearings, Gear Couplings, Gear rim/pinion drive, Gears, Heavily loaded bearings, Mills, Oscillating screen, Oven/dryer, Roller presses, High pressure grinding rollers, Separator

Food & Beverage

Safety in Production of Foods & Drinks.

Food Grade, NSF H1 registered ISO 21469 certified and FDA compliant lubricants for any food production industry.

Glass Industry

Save costs using high-performance high-temperature lubricants

Application areas: Batch House, Cold End, Hot End, Peripheral Equipment

Pulp & Paper Industry

Lubricants that meet challenging operating conditions in paper plants.

Anti Friction Bearings of Felt Rolls, Drying Cylinder, Idle Gears, White Metal Bush Bearing of Applicator Rolls, Calendar Rolls, Pope Reels, Paper Roll

Pharmaceutical

Lubricants that meet Good Manufacturing Practice (GMP) standards

Klüber lubricants are H1 registered, ISO 21469 certified and FDA compliant

Rubber & Plastic

Avoid residue formation by using Klüber lubricants

Areas: Extrusion, Film stretchers, Injection moulding, Rubber processing, Tyre manufacture – vulcanizing

Steel Rolling

Optimum lubricants for reliable production

Areas: General application, Milling, Pig Iron production, Raw material preparation, Steel production

About Klüber Lubrication

Klüber Lubrication is the leading speciality lubricants manufacturer in the world and is the leader in OEM recommended lubricants.

Klüber speciality lubricants provide an exceptional and unparalleled level of equipment protection. When you choose Klüber, you can expect lubricants that go above and beyond standard offerings in terms of quality and performance. These speciality lubricants are designed to provide outstanding protection for your equipment, ensuring its smooth operation and longevity.

Klüber’s commitment to excellence is reflected in their meticulous research, development, and manufacturing processes. They employ advanced technologies and utilize high-quality ingredients to formulate lubricants that deliver superior performance in even the most demanding environments. By choosing Klüber, you can trust that your equipment will be safeguarded against wear, friction, and corrosion, allowing it to function optimally and maintain its operational efficiency.

Furthermore, Klüber’s expertise extends to a wide range of industries and applications. Whether you operate heavy machinery, automotive systems, manufacturing equipment, or complex industrial processes, Klüber offers specialized lubricants tailored to meet the unique requirements of your specific application. Their lubricants are engineered to provide not only exceptional equipment protection but also improved performance, reduced maintenance costs, and extended service intervals.

With Klüber specialty lubricants, you can have confidence that your valuable assets are receiving the highest level of protection available in the market. Their dedication to quality and innovation ensures that you will receive unmatched performance and reliability, helping you optimize productivity, minimize downtime, and maximize the lifespan of your equipment.

We are the authorized distributor of Klüber Lubrication in Kenya, Uganda, Rwanda, and the DR Congo, and we are here to assist you in achieving your production goals. Whether you require bonded coatings, corrosion preventatives, greases, oils, pastes, release agents, sprays, waxes, or other lubrication solutions, Klüber offers a comprehensive range of lubrication products to fulfil your specific needs.