Comprehensive open-gear protection

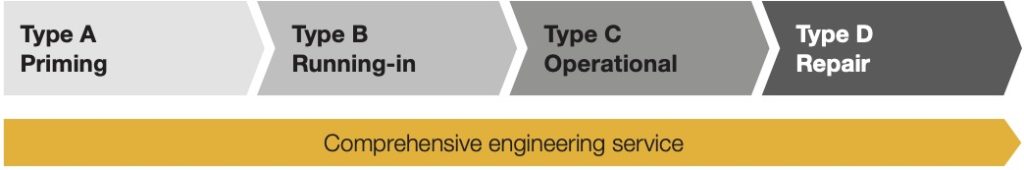

Outstanding open-gear protection starts long before the actual first revolution and accompanies the gear throughout its lifespan.

To achieve this level of gear protection, we offer a five-step lubrication process i.e.

A – Gear priming » B – Running-in » C – Operation » D – Gear Repair » Comprehensive gear service

Priming

Priming lubricants protect the tooth flanks of your gears from damage during:

1. Long-term storage

2. Initial alignment of the gears.

Lubricants can be applied manually with a brush or spatula.

Priming products:

– Klüberplex AG 11-462

– Grafloscon A-G 1 Ultra

Running-in

Running-in lubricants are applied to new gears or after repair lubrication to improve the:

1. Surface condition

2. Contact pattern and

3. Reduce the possibility of gear damage in subsequent stages.

Running-in products:

– Klüberfluid B-F 2 Ultra

– GRAFLOSCON B-SG 00 ULTRA

Operation/Service

Operational lubricants provide excellent gear protection combined with:

1. Reduced consumption

2. Higher loading capacity

3. Reduced vibrations

4. Reduced tooth flank temperatures

5. Energy savings due to low friction values

6. Approvals by all major gear OEMs.

Operation product:

– Klüberfluid C-F 3 ultra

Gear Repair

Repair lubricants re-condition the tooth flank surface by:

1. Removing asperities & scratches

2. Removing scorings to improve the contact pattern.

3. Smoothening plastic deformation up to a certain level.

Gear repair product:

– Klüberfluid D-F 1 Ultra

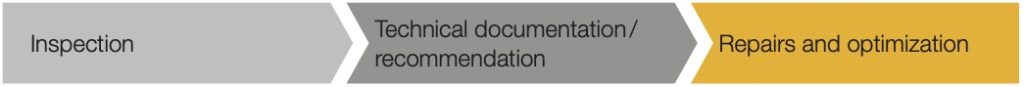

Specialized Girth Gear Services

Open-Gear Inspection

- Vibration measurements on the pinion bearings

- Tooth flank temperature readings

- Inspection of the pitch circle alignment

- Inspection of the automated spray lubrication system and the spray pattern

- Silicone rubber impressions of the tooth flank surfaces

- Visual inspection of the tooth flanks

- Assessment of the tooth flanks’ condition & load distribution

Reports & Recommendations

- Detailed reporting using inspection reports

- Photo documentation of the condition of tooth flank surfaces and the spray pattern

- Technical recommendations of corrections and improvements to prolong the gear life

- Gear damage and root cause analysis

- Optimization recommendations for your centralized lubrication system

- Reports are based on close cooperation with the OEM

Repairs & Optimization

- Repair tooth flank damage with our unique Klüberfluid D-F 1 Ultra and GRAFLOSCON D-SG 00 ULTRA gear repair lubricants

- Repairs, service and optimization of the central lubrication system, e.g. spray pattern, spray time and lubricant consumption.

- Mechanical tooth flank treatment if significant damage has occurred